In the oil field, where precision, safety, and efficiency are paramount, choosing the right valves is crucial. Various types of pumps and valves serve different purposes and offer distinct advantages. We’ll delve into the benefits of common valve types:

Ball Valves, Globe Valves, Gate Valves, and Swing Checks, & Needle Valves

Ball Valves: Ball valves are widely used in the oil field due to their excellent sealing capabilities and durability. Here are some key benefits:

- Quick and reliable shut-off: Ball valves feature a quarter-turn operation, allowing for rapid shut-off, minimizing the risk of leaks and spills. This is crucial in critical applications where safety is a top priority.

- Excellent flow control: With a full bore design, ball valves offer minimal flow resistance, ensuring efficient fluid transportation. They also provide precise flow control, enabling operators to regulate the flow rate with accuracy.

- High-pressure and high-temperature capabilities: Ball valves are well-suited for oil field operations involving high-pressure and high-temperature conditions. Their robust construction and materials can withstand demanding environments.

Globe Valves: Globe valves are known for their superior throttling capabilities and precise flow control. Here’s why they are beneficial in the oil field:

- Accurate flow regulation: The globe valve’s design allows for fine adjustments in flow control, making it ideal for applications that require precise regulation of fluid flow rates. This is especially valuable in oil field processes that demand accurate metering and control.

- Resistance to high temperatures: Globe valves can handle high temperatures without compromising performance or causing leaks. This makes them suitable for oil field operations involving elevated temperatures, such as steam applications.

- Resistance to high temperatures: Globe valves can handle high temperatures without compromising performance or causing leaks. This makes them suitable for oil field operations involving elevated temperatures, such as steam applications.

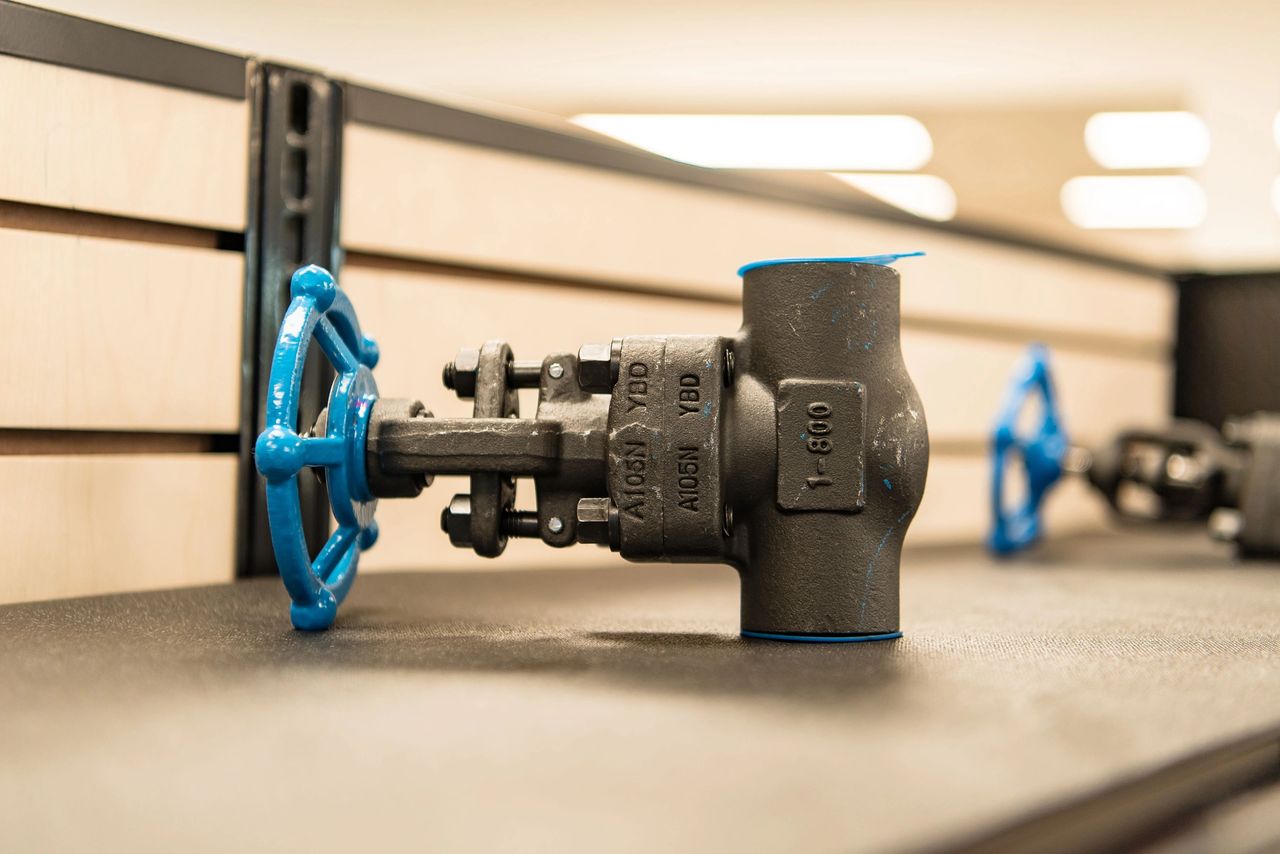

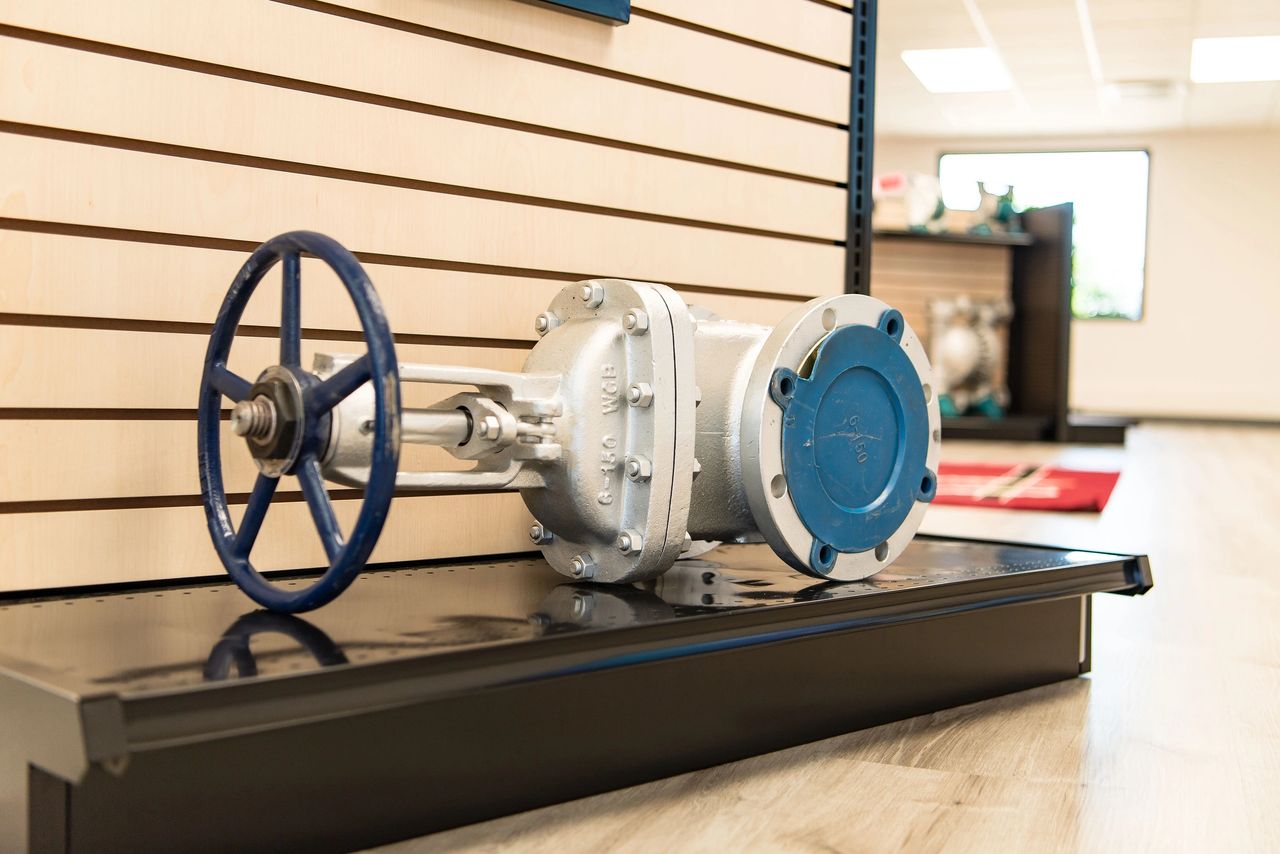

Gate Valves: Gate valves are commonly used in the oil field for their reliable shut-off capabilities and low-pressure drop. Consider the following benefits:

- Straightforward operation: Gate valves feature a simple linear motion mechanism for opening and closing, allowing for quick and easy operation. This is advantageous in situations where fast shut-off is necessary.

- Straightforward operation: Gate valves feature a simple linear motion mechanism for opening and closing, allowing for quick and easy operation. This is advantageous in situations where fast shut-off is necessary.ow rates and low pressure losses are required.

- Resilient and versatile: Gate valves can handle a wide range of fluids, including abrasive and corrosive media found in the oil field. They are known for their durability and ability to withstand harsh operating conditions.

Swing Checks: Swing check valves are widely used in the oil field to prevent backflow and protect equipment. Here are their notable benefits:

- Effective backflow prevention: Swing check valves allow fluid flow in one direction while automatically closing to prevent reverse flow. This protects sensitive equipment, such as pumps and compressors, from potential damage caused by backflow.

- Low-pressure drop: Swing check valves offer minimal resistance to fluid flow, ensuring a low-pressure drop when in operation. This characteristic is beneficial in maintaining efficient oil field processes.

- Suitable for vertical installations: Swing check valves are particularly suitable for vertical piping systems due to their self-closing nature. Their design enables reliable sealing and prevents the accumulation of fluids in the piping.

Needle Valves: Needle valves are essential components that excel in providing accurate regulation and isolation in high-pressure systems. The advantages of using a needle valve in the oil and gas industry are:

- Fine adjustment capability: Needle valves feature a slender, tapered stem with a small orifice, allowing for precise control over the flow rate of fluids. The fine-threaded stem enables operators to make small adjustments to achieve the desired flow conditions accurately.

- High turndown ratio: Needle valves provide a high turndown ratio, allowing a wide range of flow rates to be achieved with a single valve. This flexibility is advantageous in oil field operations where flow requirements may vary, enabling better adaptability and efficiency.

- Process control: Needle valves play a crucial role in various oil field processes, including refining, chemical injection, and metering.